Well, here's a Throwback for you! In 1977 Perkins was featured in an article for Minnesota Truck Merchandiser and we have a copy and wanted to share it with you! Most of it still applies, enjoy! (Photos from the original article is at the bottom of the re-typed article shown below).

THE LONGER, TALLER, HEAVIER, WIDER, THE BETTER FOR PERKINS' TRUCKERS

Hauling a conveyor assembly 145' long by 14' wide from Minneapolis to Duluth would mean nothing but headaches for most truck companies, but for Perkins Motor Transport, Savage, Minn, it was a welcomed challenge.

"My personal ambition is to haul the biggest and heaviest thing ever moved in Minnesota," said Neil Perkins, co-owner of the company with his brother Dennis. "If we haul something 99 percent of the other truck companies won't touch, I get so excited it's hard to sleep at night."

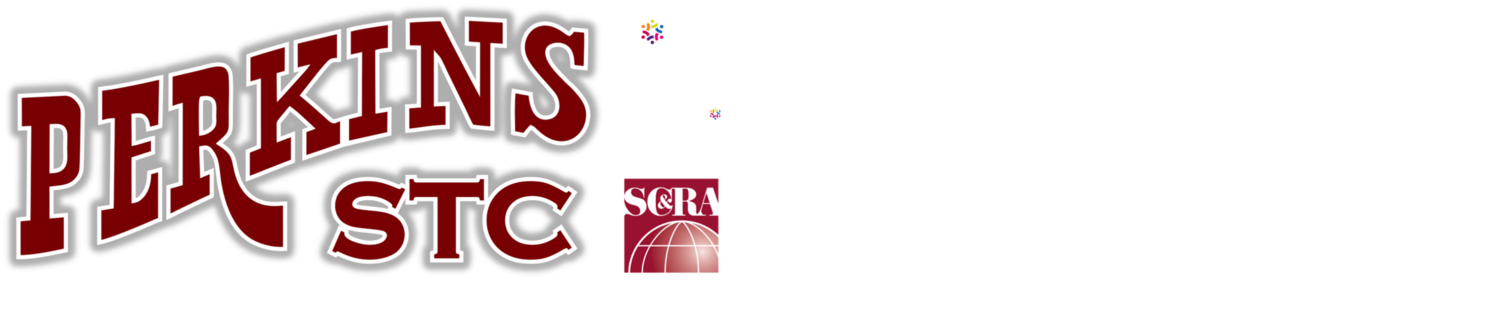

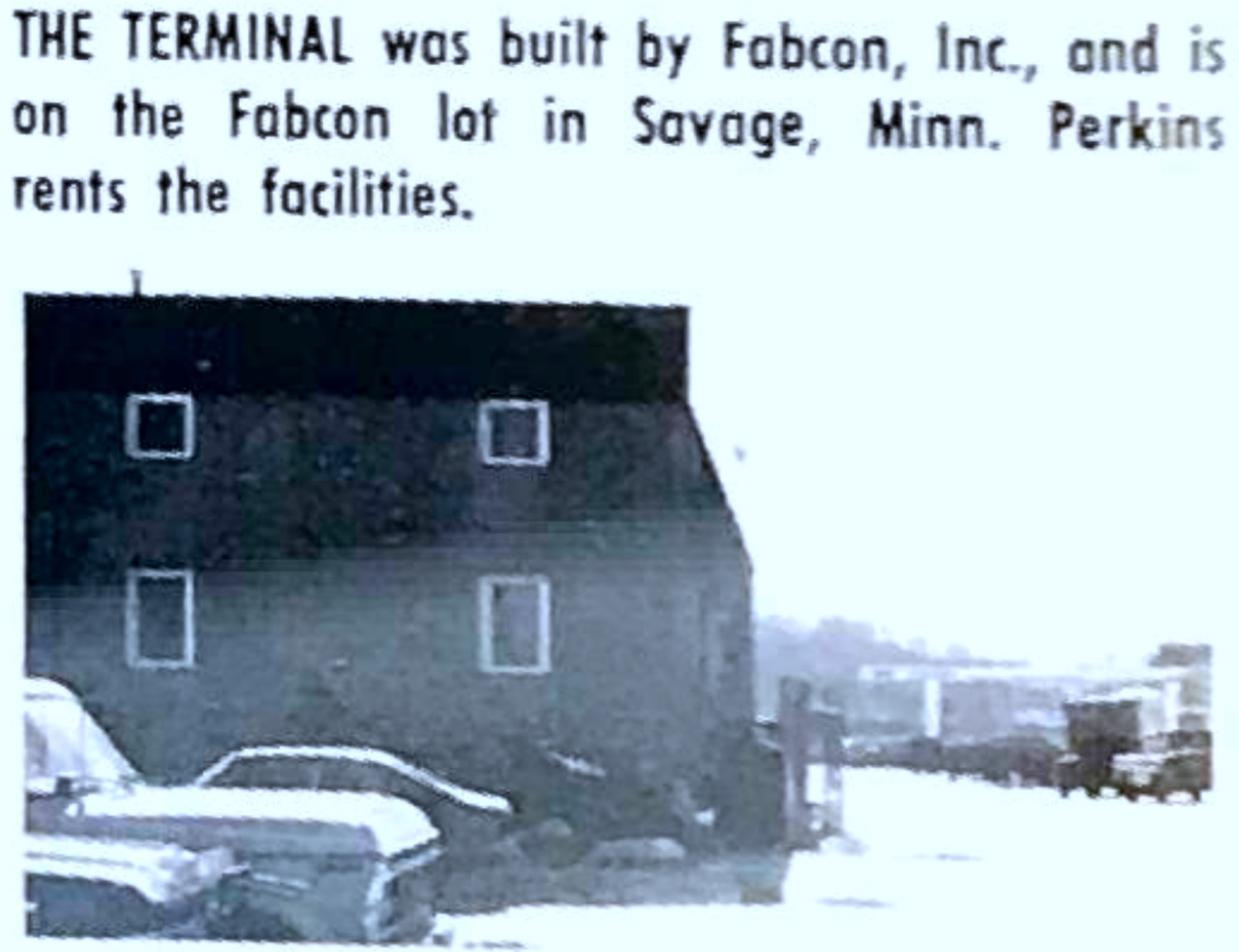

Despite the interest in over-dimensional and unusual loads, Perkins' main business is hauling heavy equipment, concrete fabrications, and steel. The company can handle everything, however, but people and petroleum. Up to 80 owner-operators are under contract at one time, which means the company owns no tractors other than a Hendrickson driven by Dean Perkins, a younger brother and has no shop. Perkins furnishes the trailer and arranges the load. The driver furnishes the tractor.

The first is unique in other ways. The first Perkins to start trucking was Neil's father Daryl, who hauled livestock beginning in 1929. At first Dennis was the only one of Daryl's sons to drive a truck. In 1971 he pulled in front of Fabcon, INc., Savage, a supplier of concrete preformed walls, decking, etc. and after "Figuring in the dirt" signed a hauling contract with them. Neil joined the trucking company in 1972 as office manager and soon began soliciting freight from other sources than Fabcon. The brothers expanded into heavy hauling in 1974 and began specializing in over-dimensional moves a year ago.

Fabcon is still the company's main contract and owns the terminal they rent, but large contract are also current with Ziegler, Inc., a Minneapolis construction equipment company, and Paper Calmenson & Co., a St. Paul steel firm. Individual hauls con come from anywhere. Dennis took in about $75,000 in 1971, and now the transit first is planning on $1 million this fiscal year.

Out of the 7,000 total hauls in 1975, about 1,000 were over-dimensional. "Loads that were unique a year ago are routine to us now," said Neil. "There isn't anything that can't be hauled, even a ten-story building."

The conveyor assembly, still the longest load, was hauled with a low boy and a dolly. The heaviest haul has been 134,000 lbs. of construction equipment. "My dream is one day the phone will right with a load over 250,000 lbs.," said Perkins.

State permits are required for over-sized loads, and in some cases, such as in the Twin Cities metropolitan area, counter permits are also. The route must be registered and arrangements made for removing and replacing any impediments like signs. Over-dimensional loads can move only between 1:30 and 5:30 in the morning. Once a sheriff's deputy stopped one of their hauls, questioned whether the permit was valid. The County Commissioners had to be awakened in the middle of the night to give the order to continue. "The governments know us by now and will grant us permits they'd be reluctant to give someone else, " Perkins claims.

Further safety requirements state that the haul must be marked "Wide Load," red flags have to fly front and rear, and amber flashing lights have to be mounted every 20 feet. The company owner claims fewer damage claims occur on unusual loads than regular hauls because of the extra precautions taken. Obstacles such as bridges, medians, and signs are planned for, and avoided if possible - in advance. A single sharp turn can take up to 45 minutes if the load is long enough.

The worst danger, however, is from the ordinary automobile driver. Despite all the warnings, the drivers tend to flash around slow-moving loads without any thought to ow much space they may have to pass. "We've talked about advertising on television and in newspapers someday to remind people to slow down and think twice in such a situations," Perkins said.

The company hauled 30 loads of conveyor trusses 17.5' wide by 92' long last spring, as well as a smoke stack that was 17' in diameter. Another peculiar load was a disassembled long cabin moved from a Minneapolis show to northern Minnesota. This year the man who makes the cabins will have Perkins haul them intact.

The toughest moves to make, however, are the tallest loads. Perkins' record so far is a houseboat 17' 10" high, 14' wide, and 67' long taken from the Bloomington manufacturer to the Mississippi River.

The firm has started a drive to have contractors meet with them before making a bid. That way they can see the blueprints and set up a transportation program that may save the contractor money. By shipping large conveyor assemblies to a Duluth site instead of a piece at a time as was originally planned, Perkins claims $50,000 was saved.

Presently the firm owns 25 trailers, including flat beds, lowboys, and extendables. The brands are Load King folding gooseneck trailers, Vulcan removable gooseneck trailers, and Air Right suspensions. The larger and larger business calls for 12 to 15 new lowboys this year and five fabricated trailers. The fabrication is achieve at Vick's Welding Truck and Trailer Repair, Savage, where the repair work is also done.

The biggest new equipment project for this year, hover, began with a rough sketch by Neil Perkins on a scratch pad. Vick Marquart, the shop's owner, is now transforming that sketch into a "modular transporter." The transporter will breakdown into three interconnectable sections. The back will have two axles as a dolly for large loads. The middle is a four-foot section with one axle which can be added to the rear if necessary. The front has a steering axle mounted behind a small cab eight inches off the ground. Extra long loads would fit over the cab. Without a shop the company not only saves on costs, but can do without mechanics and a shop foreman. Currently there are 22 owner-operators under permanent contract, four on temporary contract, and a large number of other drivers busy on specific trips. The company staff consists of Neil, who heads the operation, brother Dennis, a co-owner, and Shelley Aune, the terminal manager. Neil's wife Lina serves as the part-time secretary, and younger brother Dean drives a truck. Daryl Perkins, the father, died in 1972.

Because Neil plans to expand the business rapidly, however the office is equipment with the capacity for a much bigger operation. Starting last December all records, payrolls, etc., are handled by computer. Most of the hauling is now in Minnesota, except for the Fabcon contract which covers a five-state area. Perkins has just been granted a 48-state authority under a new contract to haul for a manufacturer of pipeline components.

For the future, the first is trying to obtain more interstate authority for his over-dimensional projects. "If we get it, there will be no gradually building up steam for the extra business," he said. "The loads have to suddenly be there or it's a bust financially." The reason lies with the cost of the Interstate Commerce Commission's Interstate common carrier permits. Perkins estimated a four-states authority for the over-dimensional business would cost about $250,000, while the same authority for seven states would be about $1 million. The price arises from the limited number of permits the ICC can allow, which is the real problem in the company's expansion since the money can be financed. To Perkins, however, the challenge of those huge loads will keep him trying.